Existing equipment and achievable processes

- Kangnuo-Geniya currently has equipment such as carving machines, slotting machines, water grinders, electronic panel saws, table saws, cold press machines, and forklifts;

Staff are responsible for drafting, order breakdown, single-panel production, and composite panel production; - Capable of performing the following processes: straight-edge cutting, opening, opening of irregular profiles, water-based coating, graphic carving, profile edging, and aluminum honeycomb composite panels;

- Stores various hardware accessories, single-panel and composite panel profiles, partition installation kits, and other materials;

- Provides technical consulting and comprehensive solutions for partitions and wall panels.

Equipment technology

Electronic saws

We offer straight-cut plunge saws for our clients. These electronic saws deliver precise, clean vertical cuts into various materials like wood, laminate, and composites. Ideal for applications requiring accuracy—such as fitting joints or creating inlays—our tools ensure controlled depth and a smooth finish. Enhance your craftsmanship with our reliable, professional-grade equipment.

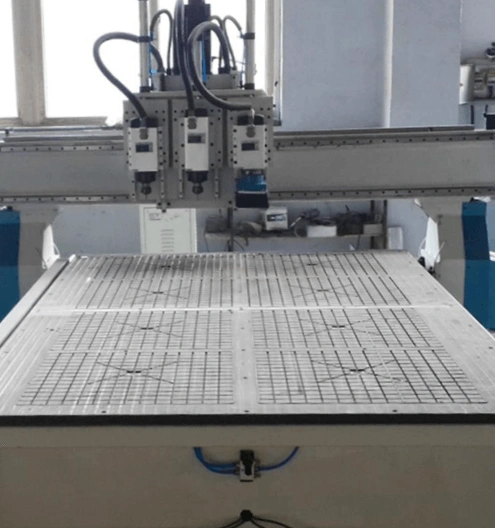

Engraving Machine

We provide professional engraving tools capable of transforming your digital graphics and designs into precisely etched creations on various materials. Bring your vision to life with our technology.

Slotting Machine

Our slotting machine specializes in creating precise grooves and rabbets (notched joints) in panel materials. It efficiently performs edge profiling and slot cutting, ensuring clean, accurate results for joinery and assembly in woodworking and furniture manufacturing.

Table Saw

We specialize in precision straight-line plunge cutting using advanced table saws. Our sliding table saws enable controlled vertical descent cuts, ensuring clean, accurate edges for dados, grooves, and inlays in woodworking and manufacturing. This technique guarantees exceptional repeatability and quality for your projects.

ink equipment

This machine performs the ink and oil sealing edge process, integrating water-based ink printing with precise UV coating application. It efficiently produces high-quality, vibrant, and durable edge banding with excellent abrasion and weather resistance. This eco-friendly solution is ideal for panel furniture and other demanding applications.

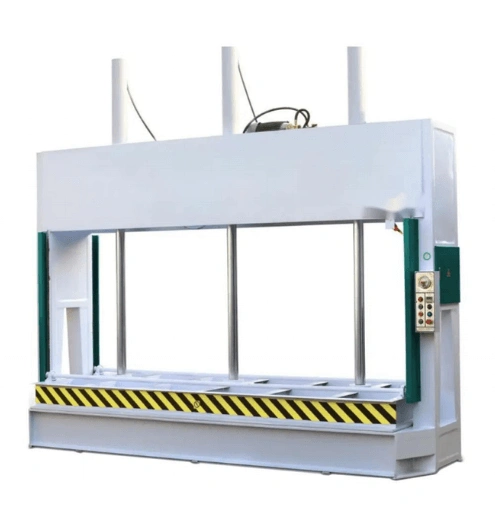

Cold Press Machine

A cold press machine uses strong, sustained pressure at room temperature to bond materials without heat. It's essential in woodworking for laminating layers, veneering, and assembling projects like furniture, ensuring strong, warp-free adhesion with clamps or hydraulic systems.

Process effect diagram

Composite Board Processing Technology

Structural Diagram

Onawei and Antibacterial Composite Boards

2、Top and bottom hinges

3、Square edge banding

4、Standard edging