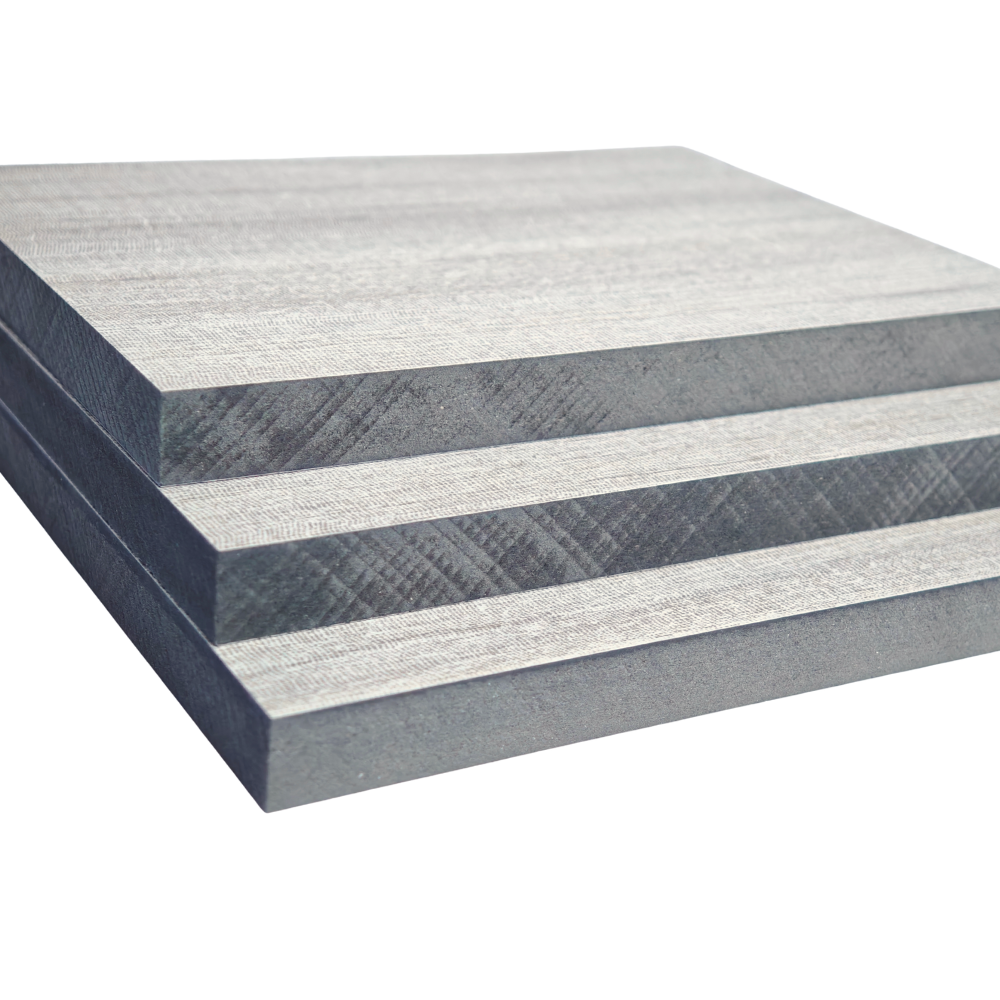

KN-Salorbear-FR

IKN-Salorbear-FR This is the latest product, and offers outstanding flame retardant along with superior

environmental credentials.

KN-Salorbear-FR

Model: KN-Salorbear-FR

ISpecification:

1. Eco Rating: ENF (FE ≤ 0.025 mg/m³);

2. Flame Retardant: B1-C Grade;

3. Moisture-Proof, Water Resistant, Center Water Absorption Expansion Rate: 24h≤5%;

4. Mildew Resistant And Anti-Bacterial, Easy To Clean;

5. Abrasion Resistance, Impact Resistant, Scratch Resistant.

Size:

1220*1830 (4*6)/1220*2440(4*8).

Thickness:

12mm/18mm/Customized.

Density:

950kg/m³.

Support:

OEM/ODM/Customized.

Surface Finished:

Solid Color, Woodgrain, Metal, Stone, Marble, Glossy, Matt etc.

Processing Services:

Custom-Sized Cutting/Veneering/Laminating/Embossing.

Applications:

Furniture, Cabinet, Toilet Partition, Door, Wall Cladding, The Billboards, The Ship Building,

The Aviation Manufacturing, Indoor Partition… Etc.

FAQ

Your board claims to be super eco-friendly. How can we verify the ENF standard, and is it recognized in our region (e.g., North America/Europe)?

We understand the importance of verifiable and locally recognized certifications. Our ENF grade (≤0.025 mg/m³) is tested according to the stringent international ISO 12460 standard, which is the core basis for many regional standards. For specific markets like North America, we can provide test reports aligned with CARB NAF requirements, ensuring compliance with the world’s most rigorous indoor air quality regulations.

You claim the board is both flame-retardant (B1-C) and highly water-resistant (≤5% swelling). How is this possible without compromising performance?

This is a key innovation. Through our advanced manufacturing process, we integrate mineral-based flame retardants throughout the board’s core, achieving B1-C rating. Simultaneously, a proprietary resin system and dense structure (950kg/m³) create an exceptional moisture barrier. These properties are built into the material, not just a surface treatment, ensuring consistent performance throughout the board’s lifespan.

How easy is it to work with this board? Can it be cut and installed using standard woodworking tools?

Absolutely. One of its major advantages is its workability. You can use standard carbide-tipped saws, routers, and drills for processing. Its high density ensures clean, sharp cuts and allows it to hold screws firmly without stripping. We also provide detailed installation guidelines to ensure optimal results.

We are interested in your OEM/ODM services. What is the process to ensure our custom requirements (size, surface) are met accurately?

We have a streamlined and transparent customization process. It starts with a dedicated project manager who will guide you from design to delivery. We provide digital proofs for all surface designs and require signed confirmation on all custom specifications (size, thickness, finish) before production, ensuring zero surprises and complete satisfaction.